What is PLM? A Guide to Product Lifecycle Management

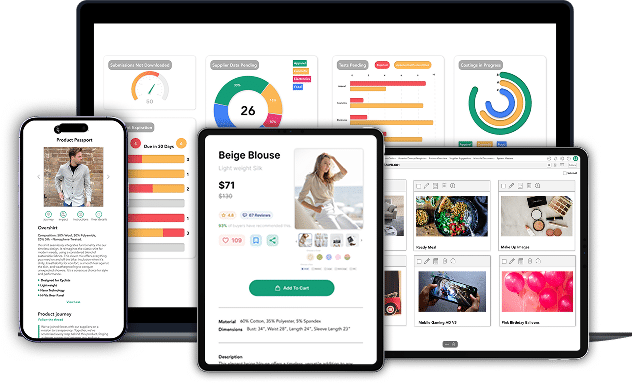

Product lifecycle management tracks a product’s journey, from conception to disposal. PLM software is a digital solution to automate and simplify the tracking process, so keeping on top of your product journey is simple.

But PLM isn’t just about managing each stage individually. It’s a holistic business process that connects the people, processes and data involved in a product so it can be developed faster, made better, and sold more successfully.

PLM creates a digital thread through product development cycles, providing real-time, end-to-end visibility and traceability.

What does PLM software do?

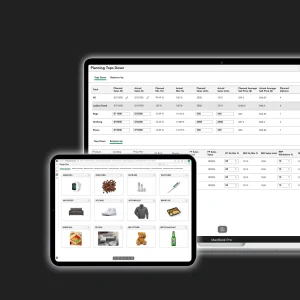

PLM software makes it easy to manage a product through its lifecycle. It puts everything in a single central location and facilitates fast communication between teams.

Let’s explore some of the key features of PLM software.

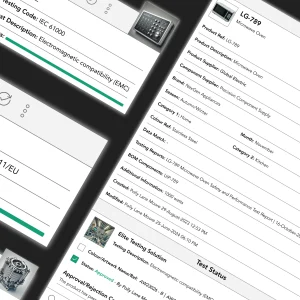

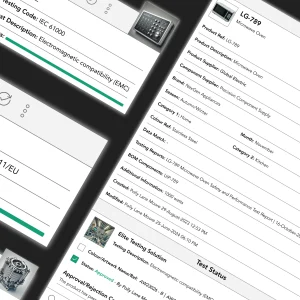

It centralises everything

In traditional product development, teams often operate in silos. This means documents and plans are stored in different places and are only accessible by the teams that created them. It’s easy for things to get lost, or for teams to be unable to access documents because they originated elsewhere in the organisation.

A PLM solution eliminates this problem by storing everything centrally, accessible through the software. So, if someone in the manufacturing team needs access to a design file to adjust, it’s right there in the app, even if they’re halfway around the world.

Everything – from CAD files and bills of material (BOMs) to specifications and planning documents – is stored safely and securely in the cloud so everyone working on the product has up-to-date, accurate information all the time.

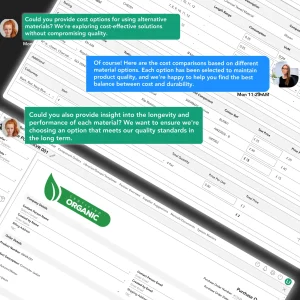

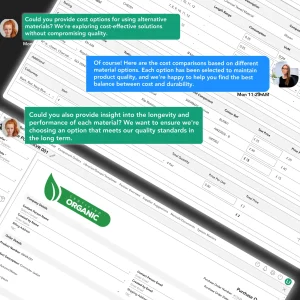

It aids collaboration

Siloed working makes collaboration between teams difficult, if not impossible. PLM software provides a single, easy-to-access communication channel for everybody involved in a product’s development.

So, that means that the manufacturing team can easily make a suggestion to the design team, without having to go through intermediaries – even if they’re on the opposite side of the world.

And it doesn’t stop there. Marketing and supply teams’ communications can run through a PLM, as well as production teams like design, engineering and manufacturing. Plus, once the product is launched, customer feedback goes in there too, so it can easily be used to iterate improvements or to inform new product design.

A PLM solution will support all the essential communication tools you need, like version control, custom workflows, and approval procedures.

Smooth collaboration

A good PLM replaces complex email threads and spreadsheets, providing a single source of truth for all your product data, designs, specifications, BOMs and more. Different teams can access the same, up-to-date information, meaning they can collaborate faster and more effectively.

Increased efficiency

PLM systems give you better visibility into your materials and processes, allowing you to make informed decisions about your use of time and resources. This paired with centralised data, you can benefit from fewer errors and expensive reworks.

Better products

Having everything laid out in front of you in a PLM system gives you tighter control over the design and development process, allowing you to identify and improve design flaws early on before they become costly issues.

Faster time to market

With the ability to automate workflows, communicate between teams more effectively, reduce reworks and manage compliance, you can bring your products to market faster with PLM and help grow your bottom line.

Compliance

The consistency and standardisation you get with PLM software helps you meet regulatory requirements and manage compliance with ease. You can make sure that all the necessary documentation and processes are adhered to at every stage of your product lifecycle.

Resilience for the future

With PLM, your brand is always ready for what the future holds. Whether it’s evolving legislation, changes in the economy or new trends in your industry, you have the information you need to adapt quickly, manage risks and continually innovate.

Smooth collaboration

A good PLM replaces complex email threads and spreadsheets, providing a single source of truth for all your product data, designs, specifications, BOMs and more. Different teams can access the same, up-to-date information, meaning they can collaborate faster and more effectively.

Increased efficiency

PLM systems give you better visibility into your materials and processes, allowing you to make informed decisions about your use of time and resources. This paired with centralised data, you can benefit from fewer errors and expensive reworks.

Better products

Having everything laid out in front of you in a PLM system gives you tighter control over the design and development process, allowing you to identify and improve design flaws early on before they become costly issues.

Faster time to market

With the ability to automate workflows, communicate between teams more effectively, reduce reworks and manage compliance, you can bring your products to market faster with PLM and help grow your bottom line.

Compliance

The consistency and standardisation you get with PLM software helps you meet regulatory requirements and manage compliance with ease. You can make sure that all the necessary documentation and processes are adhered to at every stage of your product lifecycle.

Resilience for the future

With PLM, your brand is always ready for what the future holds. Whether it’s evolving legislation, changes in the economy or new trends in your industry, you have the information you need to adapt quickly, manage risks and continually innovate.

What does PLM do?

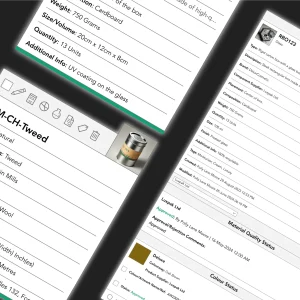

It keeps track of product changes and configurations

As a product goes through the many iterative changes needed to get it ready for production and distribution, it’s easy to lose track of which version is current and what changes have been made where. Different teams can easily end up working from slightly different product versions, causing significant problems later.

Not with a PLM solution.

With PLM, you can easily track and manage product changes, live, from your central source of truth. Everyone knows exactly what version to work from and where to find it.

The same goes for product configurations. A PLM lets you easily manage different configurations and variations.

And it uses all the essential, standard features you’d expect, like version control and check-in and out procedures.

It automates processes

Every stage of taking a new product to market involves simple, time-consuming processes and tasks. PLM software can automate those processes so you can work on the important things, like designing and building your product.

Routine tasks like document routing, approval processes and compliance checks can often be partially or fully automated in the software.

This doesn’t just save you time – it can reduce errors and speed up development cycles, too.

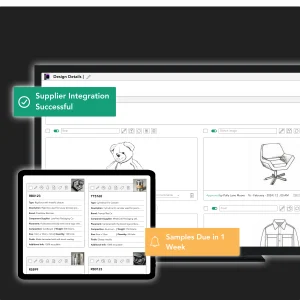

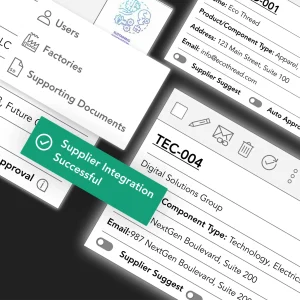

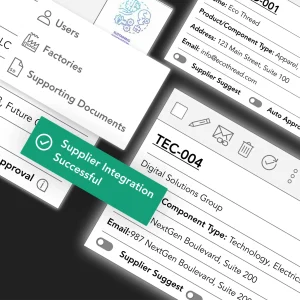

It integrates with your other systems

If you’re involved in product development and manufacturing, you know how many systems there are to make your life easier. There’s Enterprise Resource Planning (ERP), Supply Chain Management (SCM), Customer Relationship Management (CRM), Manufacturing Execution Systems (MES)… And lots more besides.

While these systems are useful and vital to a successful business, they only work if they work together.

Your PLM solution should integrate with all the other systems you need. So all the information and data you’re working with seamlessly flows through your organisation.

Loved by product people, trusted by..

What are the benefits of PLM?

A PLM does a lot. But how will using one help your organisation? What are the benefits to you? Well, there are a few.

You’ll get to market quicker

When teams work in silos, there’s overlap and there’s rework. It’s inevitable. Product development cycles can grind to a halt. Design issues can easily be missed in a sea of documents and communication threads, leading to manufacturing problems.

Using a PLM won’t eliminate all these issues. But it will improve things significantly.

It will speed up inter-team collaboration so you can build, test and rebuild faster. It will reduce overlapping tasks and rework, so no time is wasted. And it will make managing design or manufacturing problems simpler, so delays in getting to market are minimised.

You’ll get a better quality product

There’s always a tradeoff between budget and quality. But using a PLM solution helps you make the most of your budget, so you end up with a better quality product. When you get to market, a better product means more sales, happier customers and – ultimately – more profit.

PLM software makes it simple to implement fast, continuous feedback and improvement loops, so you can quickly and efficiently iterate better versions of your products. It helps you with rigorous change management, so you can maintain standards as your product progresses through the development and manufacturing processes. It even integrates things like simulation and testing results to help reduce defects and recalls.

You’ll save money

PLM software saves money by increasing efficiency. You can then invest that money back into creating a better product or use it elsewhere.

But that’s not the only way a PLM solution saves you money.

A PLM can help you build a more optimised manufacturing process that reduces waste and lowers production costs. And better supply chain visibility can help you reduce inventory and procurement expenses.

You’ll be more innovative

Creating an innovative product helps you to stand out in the market and sell more units. But finding the time and headspace for innovative thinking is hard when you’re stuck in a hectic product development cycle.

A PLM helps you to find that space.

It makes every part of a product’s lifecycle more efficient, freeing up time for your design teams to be creative and innovative. It also provides simple, centralised communication that lets all your teams work together, sharing ideas freely. And it makes it simple to rapidly prototype and experiment, so teams can try new approaches quickly and efficiently.

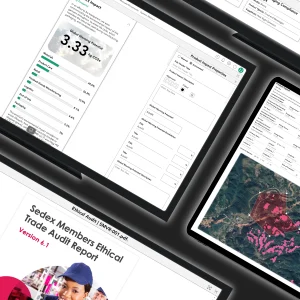

You’ll find it easier to maintain standards

Depending on your product, you could have a lot of standards and legal requirements that must be satisfied before it can be sold. A PLM makes it much easier to keep track of those standards. It also ensures that changes and iterations made to the product, both before and after it goes to market, don’t affect its compliance.

And, of course, it will keep a detailed and easy-to-access audit trail with all the documentation and evidence you need for your certifications.

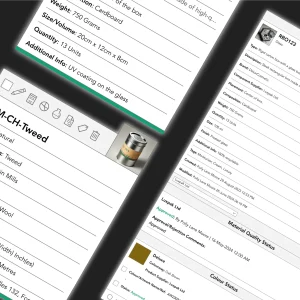

You’ll be more sustainable

A holistic view of a product’s full lifecycle helps support eco-design principles and end-of-life planning. Every stage of development and production can be tailored towards creating a more sustainable product.

A PLM solution helps meet your environmental goals and customers’ sustainability expectations.

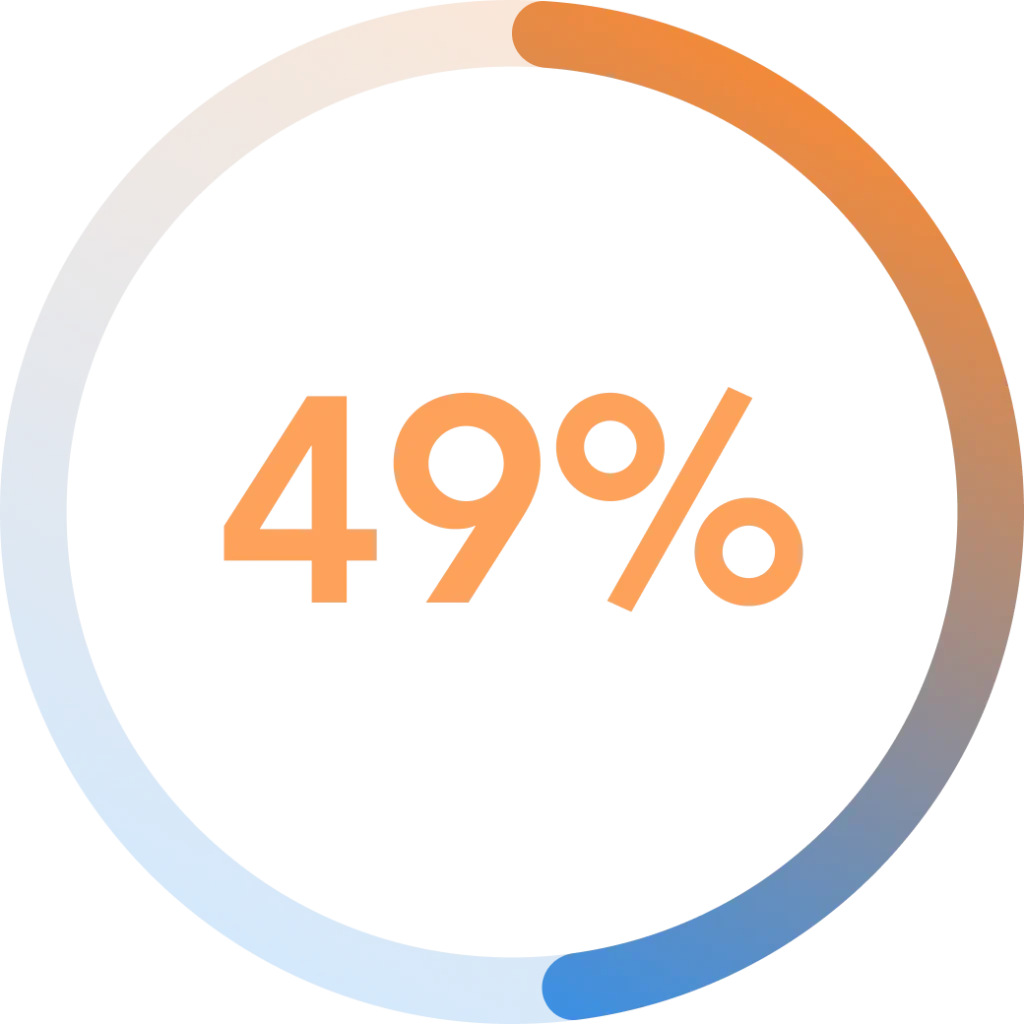

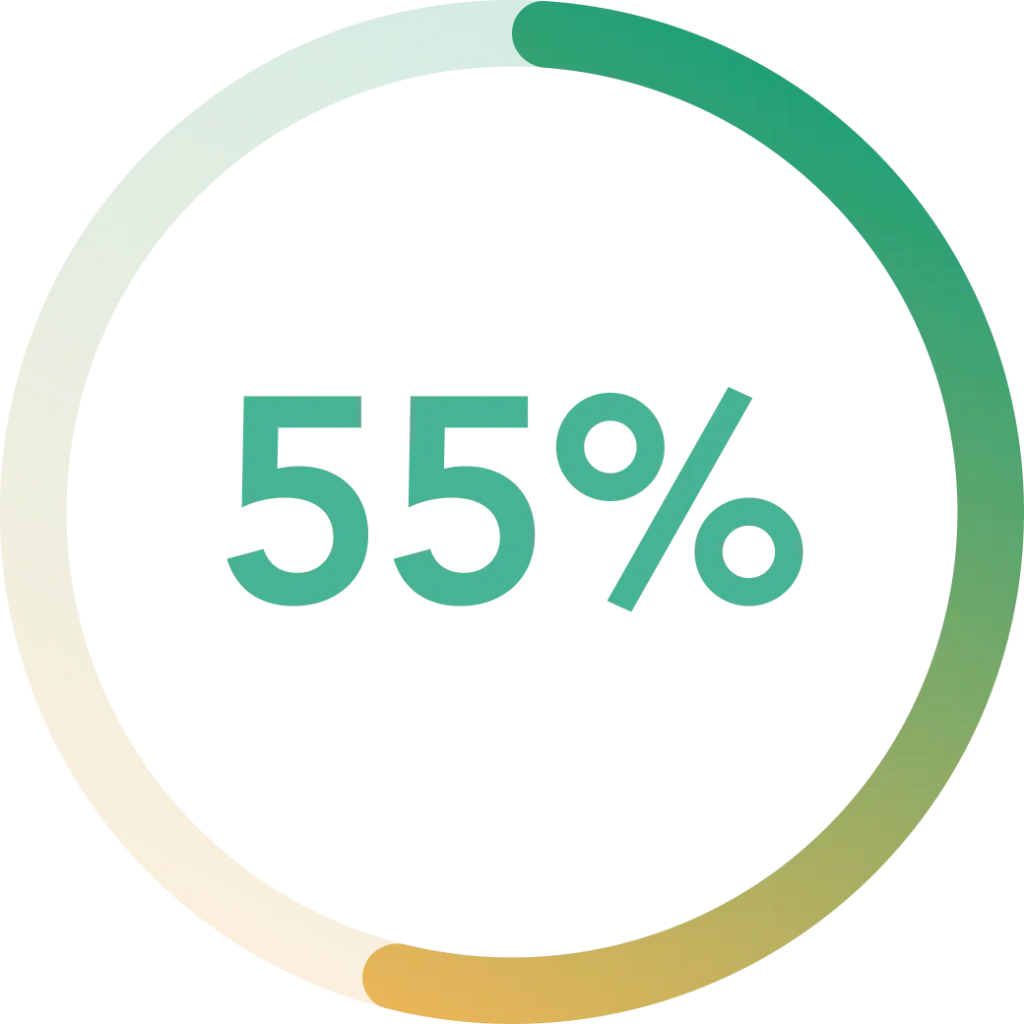

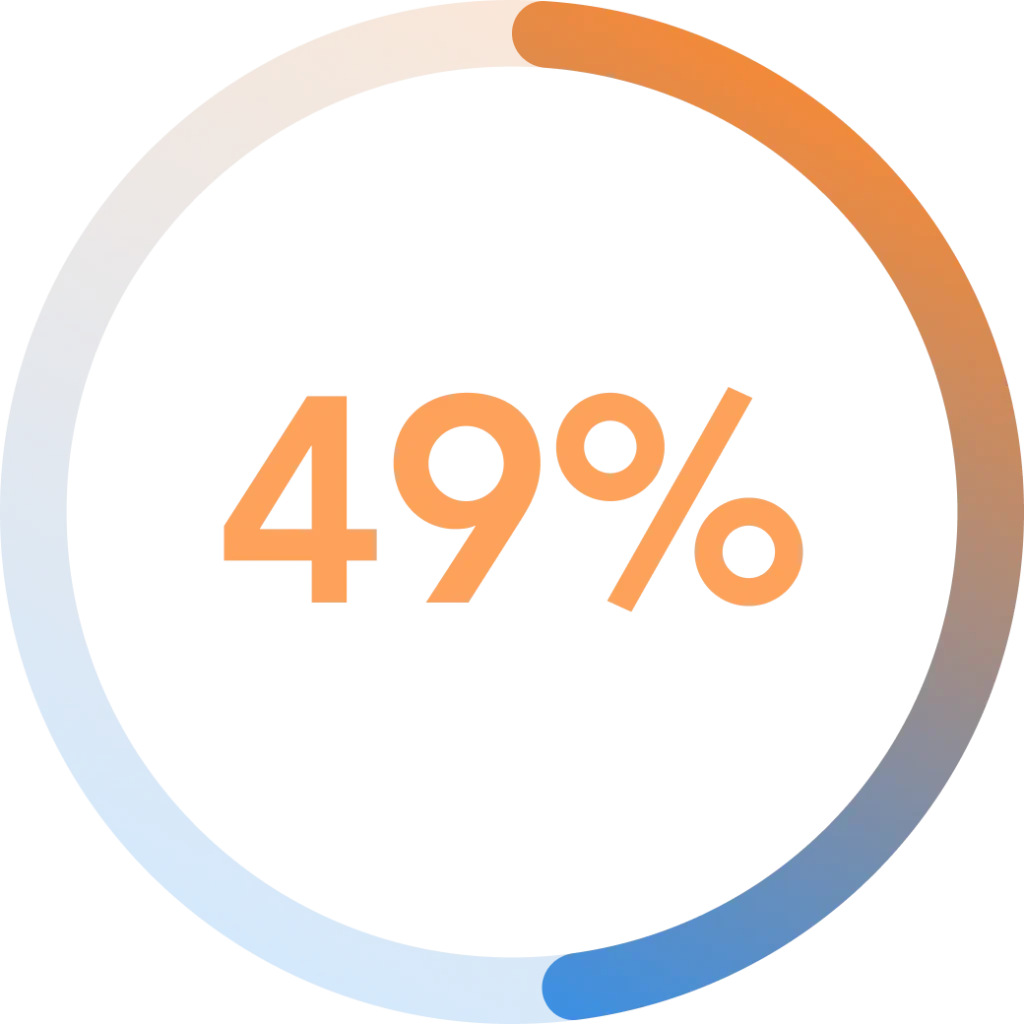

New products arrive late to market

Can't access the data they need

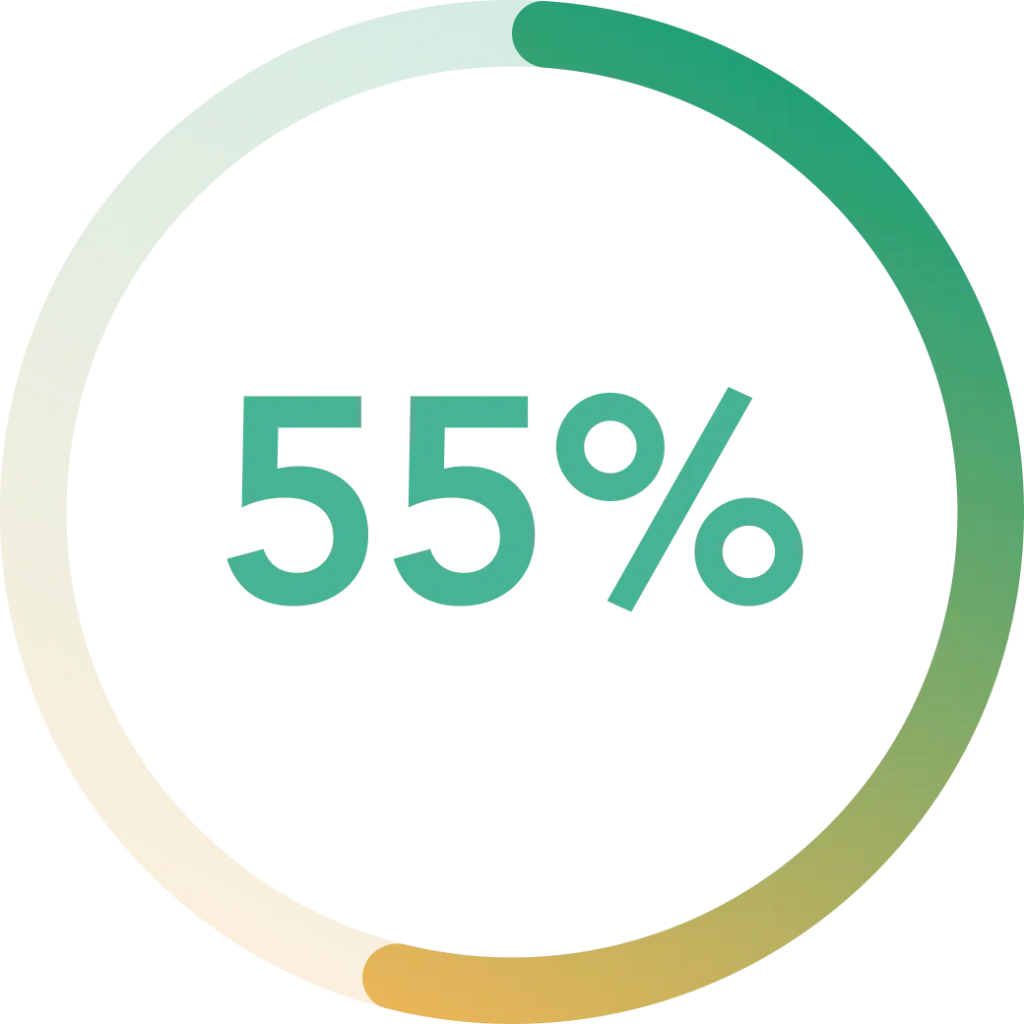

Of each week is wasted on data retrieval

Struggle to share info cross-functionally

Make decisions on outdated data

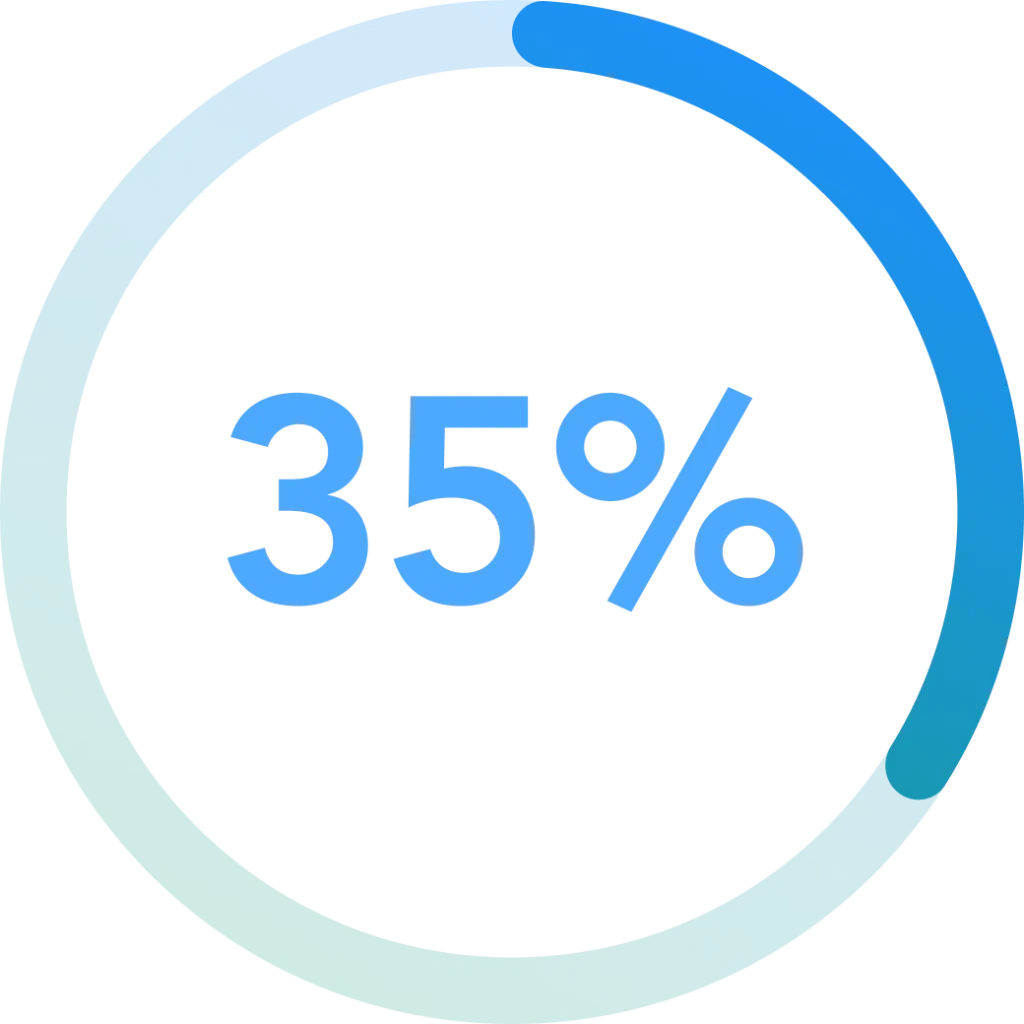

New products arrive late to market

Can't access the data they need

Of each week is wasted on data retrieval

Struggle to share info cross-functionally

Make decisions on outdated data

What are the stages of a product’s life cycle?

Of course, not every product has the same journey. But most will go through a broadly similar process, which looks something like this.

Concept

The beginning of the journey always starts with an idea. Then, that idea is developed into a viable, marketable business prospect through market and competitor research.

Design & development

Once the idea is finalised, it must be turned into a real product. It needs to be designed, simulated and analysed. Then, prototypes need to be built and iterated until the product is ready for sale.

Production

When the design process is complete, the product needs to be made. The manufacturing process needs to be planned, the supply chain needs to be managed, and production needs to be scheduled. Quality control needs to be implemented, and change management procedures put in place.

Marketing, distribution and sales

Then, when the product is ready, you need to sell it. The launch needs to be planned, distribution logistics sorted, and channels managed. Pricing needs to be finalised, promotions need to be run, and customer feedback should be collected.

Service and support

Once the product is in the wild, support is vital. Warranty claims and repairs need to be managed, customers need technical help and troubleshooting, and if the product is digital it may need patches and fixes. Data collection should also continue, to inform future designs.

End of life

Every product has a lifespan. Eventually, it will be phased out or replaced. If it’s a physical product, it will need to be disposed of in an environmentally friendly and sustainable way. And the lessons learned need to be retained and assimilated for future projects.

Concept

The beginning of the journey always starts with an idea. Then, that idea is developed into a viable, marketable business prospect through market and competitor research.

Design & development

Once the idea is finalised, it must be turned into a real product. It needs to be designed, simulated and analysed. Then, prototypes need to be built and iterated until the product is ready for sale.

Production

When the design process is complete, the product needs to be made. The manufacturing process needs to be planned, the supply chain needs to be managed, and production needs to be scheduled. Quality control needs to be implemented, and change management procedures put in place.

Marketing, distribution and sales

Then, when the product is ready, you need to sell it. The launch needs to be planned, distribution logistics sorted, and channels managed. Pricing needs to be finalised, promotions need to be run, and customer feedback should be collected.

Service and support

Once the product is in the wild, support is vital. Warranty claims and repairs need to be managed, customers need technical help and troubleshooting, and if the product is digital it may need patches and fixes. Data collection should also continue, to inform future designs.

End of life

Every product has a lifespan. Eventually, it will be phased out or replaced. If it’s a physical product, it will need to be disposed of in an environmentally friendly and sustainable way. And the lessons learned need to be retained and assimilated for future projects.

PLM for sustainablility

PLM is key to sustainability, empowering teams to design with sustainability in mind – choosing eco-friendly materials, reducing waste through precise planning and streamlining production to minimise environmental impact. Thanks to greater transparency, you can track and verify ethical practices across your supply chain with ease. With PLM, you can not only meet sustainability goals but also build trust with eco-conscious consumers, proving that profitability and planet-positive practices go hand in hand.

What to look for in PLM software

User friendly interface

Scalability

Integration capabilities

Collaboration features

Testing and compliance management

Configuration and customisation

BOM and quality control

Data security

Analytics and reporting

Cost and negotiation management

User friendly interface

Scalability

Integration capabilities

Collaboration features

Testing and compliance management

Configuration and customisation

BOM and quality control

Data security

Analytics and reporting

Cost and negotiation management

Conclusion

Product lifecycle management isn’t just another business buzzword. It’s a framework that transforms how organisations develop, manufacture, and support products. Implementing a PLM solution has major benefits, like faster time-to-market, better quality products, cost savings, more innovation, easier compliance, and greater sustainability.

By centralising information, supporting collaboration, tracking changes, automating processes, and integrating with other business systems, PLM creates a single source of truth that lets teams communicate and work across geographical boundaries and organisational silos. This holistic approach streamlines operations and creates space for creativity and innovation.

Whatever you’re developing, embracing PLM principles and technology helps your organisation deliver better products more efficiently. As product lifecycles speed up and sustainability concerns grow, having a comprehensive PLM strategy isn’t just good business practice. It’s a competitive necessity.

Get free forever PLM software

Bombiix is a powerful PLM that places you at its heart, managing every stage of your product development process with clarity and efficiency.

And it starts from just £0 per month.

PLM FAQs

Below, we answer some of the most frequently asked questions about PLM

Why is PLM important for businesses?

PLM helps businesses streamline product development, improve collaboration across departments, reduce time to market, and enhance product quality. It also enables better management of product-related data, leading to reduced costs and increased profitability.

How does PLM differ from ERP?

While PLM focuses on managing the entire lifecycle of a product, from concept to end-of-life, ERP (Enterprise Resource Planning) manages core business processes such as finance, HR, and supply chain. PLM is more design and innovation-oriented, while ERP is more about operational efficiency.

What industries benefit from PLM?

PLM is beneficial across various industries, including manufacturing, automotive, aerospace, electronics, consumer goods, fashion, food and pharmaceuticals. Any industry that requires detailed product design, development, and collaboration can leverage PLM.

What are the key components of a PLM system?

Key components of a PLM system include product data management (PDM), project management, computer-aided design (CAD) integration, bill of materials (BOM) management, change management, and document management. These tools help in managing every aspect of product development.

How does PLM support innovation?

PLM provides a centralized platform for managing ideas, designs, and feedback throughout the product development process. It enables teams to collaborate effectively, reduce errors, and quickly adapt to market changes, thus fostering innovation.

What are the benefits of using cloud-based PLM solutions?

Cloud-based PLM solutions offer flexibility, easier scalability, lower upfront costs, and remote accessibility. They allow teams to collaborate across geographies and make it easier to integrate with other cloud applications, ensuring data consistency and real-time updates.

Can small businesses use PLM?

Yes, PLM solutions are available for businesses of all sizes. Small and medium-sized enterprises (SMEs) can use PLM to improve collaboration, reduce product development costs, and manage product data more efficiently. Many vendors offer scalable and affordable PLM solutions tailored to smaller businesses.

What challenges might a company face when implementing PLM?

Common challenges include resistance to change, high initial setup costs, integration with existing systems (such as ERP or CRM), and training employees to use the new software. A clear implementation strategy and choosing the right PLM solution can help overcome these challenges.

How can I choose the right PLM software for my company?

Consider factors such as your company’s size, industry-specific needs, ease of integration with other systems, user-friendliness, and budget. It’s also essential to evaluate the scalability of the PLM solution to ensure it can grow with your business.

How does PLM help with regulatory compliance?

PLM systems can streamline regulatory compliance by providing a centralized repository for all product-related documentation, including design specifications, testing results, and change history. This ensures that companies can quickly access necessary data for audits and adhere to industry standards and regulations, such as ISO, FDA, or environmental requirements.