A guide to product lifecycle management

What Is Product Lifecycle Management (PLM) And Why Does It Matter?

Product Lifecycle Management (PLM) is the process of strategically managing your product’s entire journey – from initial concept, all the way through to design, manufacturing, service and end-of-life disposal.

A PLM system or PLM software helps you manage all your product data, processes and people involved in this journey, unifying everything into a single source of truth.

Simply put, with a PLM in your toolbox, you have more control over product development – smoother communication, easier collaboration and the ability to bring better products to market faster.

Below, we outline everything you need to know about the PLM process and PLM software.

What is PLM software used for?

PLM software is used by engineers, designers, manufacturers and product managers in a wide variety of industries, such as fashion and apparel, consumer goods, electronics, automotive, aerospace and defence and pharmaceuticals.

Connecting teams across design, supply chain, quality, and operations, a PLM system ensures accurate data, faster collaboration and better product outcomes.

The core stages of the product lifecycle

Typically, there are six key stages to the product lifecycle management process.

Idea generation and conceptualisation

Spark a new idea for a great product.

The first stage of the PLM process is all about taking an idea and shaping it into a structured plan. Align creativity with commercial goals by defining product concepts, exploring feasibility and building out range or seasonal plans.

Design and development

Bring your vision to life.

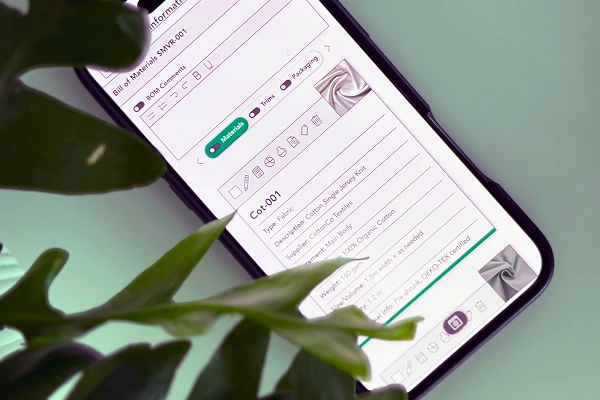

It’s time for designers and product developers to create a detailed plan for the product. Think sketches, specifications, tech packs, bill of materials (components), measurements and more. Clear and accurate data from the start is vital for reducing costly mistakes later down the line.

Sampling and testing

Perfect every last detail.

Before production begins, products go through rounds of sampling, fitting, and testing. This stage of the PLM process focuses on refinement, checking that every material, colourway and measurement meets expectations. Sampling brings confidence that your final product performs as planned, while testing covers compliance and quality.

Manufacturing and production

Turn plans into products.

Once everything is approved, production can begin. Manufacturing partners and suppliers must work in sync to bring the product to life. A well-managed supply chain keeps everyone aligned, reduces delays and ensures that what was envisioned in the design room reaches the customer exactly as intended.

Launch, marketing and sales

Get your product in front of customers.

With production complete, it’s time to launch. Marketing, merchandising and sales come together to position the product, plan campaigns and get it into stores – physical or digital. Consistent, accurate information across every channel helps tell a unified story and deliver a smooth buying experience.

Service and end-of-life care

Life beyond the sale.

The product lifecycle management process doesn’t stop with the sale. Post-sale data helps you monitor performance, customer satisfaction and returns. Meanwhile, traceability, sustainability and end-of-life care are becoming an increasingly significant part of a product’s journey.

Why is product lifecycle management (PLM) so important for your business?

The benefits of PLM speak for themselves – just take a look at some of the advantages below.

PLM software is no longer an expensive luxury, but an absolute necessity for brands that want to remain resilient and thriving for years to come.

Get products to market faster

With your data, teams and suppliers all connected, decisions are made with confidence, delays disappear and you can bring products to market faster.

PLM software gives you full visibility of your timelines, so you can spot bottlenecks early and keep launches on track.

Ensure quality and consistency

PLM allows you to build consistency into your product development process. From first sketch to final sample, PLM keeps every detail aligned, resulting in fewer errors and smoother sign-offs. Specs, test results and supplier approvals all live in one clear space, so nothing slips through the cracks.

Drive collaboration across all teams

PLM brings teams together – from product design and development to manufacturing and marketing. It removes the need for back-and-forth emails, complicated spreadsheets and silos of duplicated information. Instead, everyone works with the same up-to-date information. Feedback is fast, communication is clear and teamwork feels effortless.

Reduce product development costs

PLM unchains you from unnecessary admin costs that eat into your margins; the duplication of data, the guesswork and the endless feedback cycles. By uniting your product data and automating manual tasks, you make smarter use of your resources, freeing your team to focus on innovation, not firefighting.

Support compliance and sustainability goals

The key to compliance is clear, easily accessible data, and that’s exactly what PLM facilitates.

With one central source of truth, you can respond quickly to changing legislation and stay ahead of new requirements. It gives you complete visibility, right down to the smallest details of your product information, so you’re always in control and audit ready.

Loved by product people, trusted by..

“As a forward-thinking business, we always seek solutions to boost efficiency and ease workloads. A PLM system was the logical choice for managing data in creating a Digital Product Passport. Switching to PLM brought big changes, but our team embraced it because Bombiix provided solutions that fit our processes—and most importantly, they wanted to use it.”

Lucy Gledhill

Founder, Joanie Ltd

Bombiix has been a game-changer for Fimex—it just works with us. In a fast-paced environment where things can get hectic, Bombiix is always there, and a reliable single source of truth for our business.

It’s the perfect tool for our teams across the factory, sales, merchandising, and design, giving everyone seamless access. I’d have no hesitation in recommending Bombiix—it’s an excellent solution that truly supports our workflow.

Caroline Davies

Chief Executive Officer

One word that I would use to describe my experience with Bombiix is fresh. Everything about the system and interface looks fresh and clean, but also the way the system is operated, the human touch. All of that is very fresh for me in the world of PLM. Bombiix is not just a software-driven computer robot system that looks like it’s from 1995.

Michaela Silverman

Design and Buying

” Running a production agency used to be chaos until we found Bombiix. It’s intuitive, tailored to our industry, and backed by a team that truly gets fashion (and isn’t afraid to customise where needed). Finally, a system that speaks our language and a joy to work with, too.”

Fazane Fox

Managing Director

How PLM software is different from PDM and ERP

PLM, PDM, ERP – it’s easy to get confused with the different acronyms and types of product software available in today’s market.

Each system plays a different role

Stores, organises and controls technical data.

Manages a company’s core business operations.

Supports you from concept and design through development, production and launch.

PDM (Product Data Management) focuses on the data behind the design.

Mainly used to store, organise and control product information, your PDM is a digital filing system for CAD files and technical drawings. It keeps everything structured, secure, and accessible, so teams always work from the latest version.

PDM is a repository of information and PLM helps you take this information and move your product from concept to market.

ERP takes over once the product is ready to hit production and the market.

Managing the business side of your product data, your ERP is for purchasing, inventory, logistics, finance and HR.

PLM helps you bring your product from concept to market and ERP helps you deliver it efficiently and profitably.

When ERP and PLM are integrated, you get a continuous digital thread – from first sketch to store shelf.

Traditional ERP and PDM alone can’t keep up with the speed and complexity of today’s product development cycles.

A modern PLM closes the loop, bringing real-time visibility, automation and collaboration across your product lifecycle.

PLM turns the static information in ERP software and PDM systems into connected, intelligent workflows.

Why product people choose Bombiix over traditional PLM systems

Bombiix is revolutionising PLM – placing product people at the centre to support every stage of your product development process.

Built by product people, for product people

Traditional PLMs were built for processes, not for people. Bombiix changes that.

Designed by people who’ve lived it

Late nights, shifting deadlines and spreadsheet chaos – we’ve been there. We’ve felt the pressure, the passion and the pride that come with building great products, and we designed a platform that finally supports that journey.

A complete solution, from concept to production

Where traditional PLMs fall short, Bombiix goes further. Gone are the days of clunky, rigid systems that only add to your workload. Instead, Bombiix connects every stage of your product journey and is customisable to how your team works.

A modern, intuitive platform

Bombiix mirrors the intuitive, creative flow of product development – simple, visual and built to make sense at every stage.

No hidden tiers - one clear subscription

We’re clear on costs from the beginning, so there’s no hidden surprise later down the line. No version lock-ins, paid upgrades or feature gates – you get it all as we evolve and update the system.

Adapts to your processes, scales with your business

Finally, a PLM that fits your flow. Unlike one-size-fits-all systems, Bombiix adapts to you. Create bespoke modules and add custom fields to create an intuitive system that scales with you.

Fast onboarding, zero setup fees

Start seeing value in months, not years. With Bombiix, implementation is handled directly via chat and live sessions with real people who have lived your daily challenges.

Focused on the future of product development

Bombiix is continuously evolving to reduce your workload and keep your business ahead of what’s next.

Affordable intelligence for every member of your team

Bombiix gives you the power of a full product team assistant. Automate repetitive admin, surface insights instantly and make better, faster decisions without the need for costly integrations or data analysts.

Sustainability built in, not bolted on (DPP-ready)

With sustainability woven through every process, Bombiix helps you trace materials to Tier 4, track ethical sourcing and automate Digital Product Passports (DPPs). You get the right data at the right time, making it easy to design responsibly and prove your product’s impact.

Ready to take back control?

Bombiix is a powerful PLM that places you at its heart, managing every stage of your product development process with clarity and efficiency.

And it starts from just £0 per month.

PLM FAQs

Didn’t get the answer you were looking for? Here are some of the most commonly asked questions about product lifecycle management software.

What does PLM stand for?

PLM stands for Product Lifecycle Management, which refers to the strategic, end-to-end approach to managing a product from the initial idea through its end of life.

Which industries use PLM software?

Any business developing a physical or software product can benefit.

While initially adopted by manufacturing, PLM software is now used across various industries, including retail, automotive, aerospace, high-tech and consumer products.

What are the key benefits of implementing a PLM system?

PLM brings many benefits to businesses, including faster time-to-market, reduced development costs, easier collaboration between teams, and greater confidence in compliance with regulations.

What is the product lifecycle management process?

The core PLM process generally involves four main phases: conception/ideation, design and development, production/manufacture and service/end-of-life.

How long does it take to implement PLM software?

Traditional, legacy PLM systems can take months, or even years, to implement. Modern, cloud-native solutions like Bombiix, however, have a fast onboarding and can deliver value in days, not months, with support handled directly via chat.