Ever had a fabric shipment arrive late and suddenly your whole collection slips behind schedule? Or found yourself chasing suppliers because sample approvals are stuck in limbo? In fashion, one small delay can snowball into missed launches, extra costs and a lot of unnecessary stress.

The critical path method solves this, giving you a clear roadmap that helps you spot bottlenecks early, keep suppliers accountable and bring products to market on time.

In this guide, we break down what the critical path really means in fashion, why it’s so important and how to set one up step by step.

We’ve packed everything into this article – from the benefits and common pitfalls to how PLM software like Bombiix makes the process a lot easier.

Keep reading to see how you can stay in control and focus on creating products your customers love.

Are you tight on time? Quickly jump to a section:

- Critical path meaning – quick definition

- What is the critical path method (CPM)?

- Why is the critical path important in fashion?

- Step-by-step guide: How to set up a fashion critical path

- Benefits of the critical path method

- Common mistakes in critical path management

- How Bombiix simplifies critical path management

- Critical Path FAQs

Critical Path Meaning – Quick Definition

In simple terms, the critical path is the sequence of tasks that must be completed on time for a product to launch as planned. If any of these tasks are delayed, your whole schedule slips.

In the context of fashion, your critical path might include fabric sourcing, sample approvals, product placement and shipping.

And each step has dependencies – for example, you can’t approve a final sample until materials arrive. Therefore, mapping these tasks is vital for staying on schedule.

What is the Critical Path Method (CPM)?

The critical path method is a project planning technique dating back to the 1950s. Today, it’s common in construction, engineering and increasingly in fashion.

The method helps you:

- Break down every activity in your production cycle.

- Identify dependencies and what needs to happen before something else can start.

- Calculate the total time needed for production.

- Pinpoint the longest chain of dependent tasks – i.e. the “critical path”.

Critical path method vs critical path analysis: What’s the difference?

Critical Path Method (CPM)

Map out tasks, dependencies and timings.

Critical Path Analysis (CPA)

Review your plan to understand where risks or delays could appear.

Why is the Critical Path Important in Fashion?

1) Avoid missed deadlines

Fashion runs on seasonal calendars. If you miss a delivery window, you not only risk delays, but also risk missing the season entirely. A critical path shows you exactly which tasks you can’t afford to slip.2) Manage supplier dependencies

It’s common for brands to work with multiple suppliers across different countries. Without a critical path, it’s difficult to see how one late fabric delivery impacts sample approvals, production slots and shipping. With a critical path, you spot risks early and communicate clearly with suppliers.3) Reduce bottlenecks and risks to your business

Bottlenecks often appear in testing, sample approvals, and factory capacity. A clear path helps you see them coming and plan around them. It also gives you evidence to share with your team or board when explaining why a delay might impact delivery.Step-by-Step Guide: How to Set Up a Fashion Critical Path

It’s daunting to set up a critical path if you’ve never done it before. Below, we break down the steps:

Step one: Map every task and milestone

List all activities needed to bring your product to market. Include fabric and trim sourcing, first and second samples, sealed samples, purchase orders, production and shipping.

Step two: Identify dependencies and lead times

Mark which tasks rely on others being completed. For example, you can’t create a sealed sample until your first sample is approved. Also, add realistic lead times for materials and trims.

Step three: Build your timeline

Create a timeline showing when each task should start and finish. Highlight the longest chain of dependent tasks. That’s your critical path.

Step four: Track, update and communicate

Your path isn’t static. Update it regularly as circumstances change. Share updates with your team and suppliers so everyone works from the same information.

Step five: Bring clarity and consistency to your critical paths

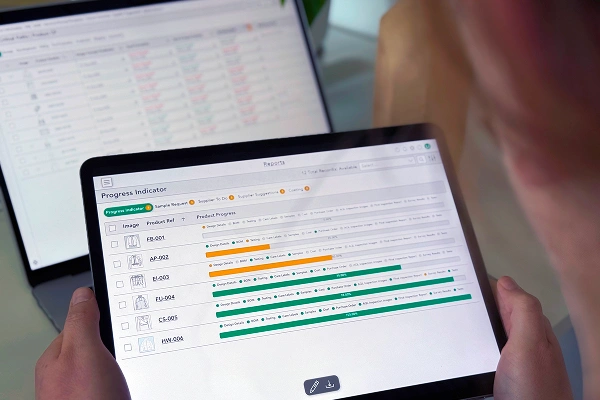

Whether you’re launching seasonal collections, tracking development and approvals or managing delayed shipments, Bombiix helps you break down every product’s journey into manageable, trackable tasks that reflect your team’s unique processes.

- With full customisation, powerful automation and built-in reporting tools, you’re always one step ahead:

- Monitor progress of each product, colourway or PO.

- Identify bottlenecks before they affect you.

- Set automatic task dependencies.

- Pull live PLM data – never input the same info twice.

- Planned vs actual reporting.

Benefits of the Critical Path Method

Using the critical path method brings a multitude of benefits for your fashion brand:

- Confidence in timelines – know your exact delivery windows.

- Better resource allocation – avoid wasted time and effort on tasks that don’t impact the launch.

- Improved communication – keep suppliers and internal teams aligned with one shared plan.

- Risk management – spot issues early and plan around them before they become critical.

Common Mistakes in Critical Path Management

Beware of these common pitfalls when it comes to critical paths:

- Not including all tasks – missing a key milestone like packaging approvals can throw off your schedule.

- Ignoring non-critical tasks – these can still cause problems if overlooked.

- Over-promising on timelines – build in buffer time for supplier delays, holidays and shipping.

- Failing to update the path – a static path quickly becomes outdated and useless.

How Bombiix Simplifies Critical Path Management

Most brands still track their critical paths in spreadsheets, which are prone to errors and quickly get messy.

Bombiix replaces them with live, automated critical paths inside your PLM.

This means you can:

Build and update timelines in real time

Integrate supplier lead times directly

Get alerts when deadlines are at risk

Connect the critical path to your PLM

Instead of chasing updates, you get full visibility – and the confidence that comes with it.

Critical Path FAQs

What is a critical path in project management?

It’s the sequence of tasks that determines the shortest possible time to complete a project. If any critical task is delayed, the whole project is delayed.Can the critical path change during a project?

Yes. Lead times, test results, factory capacity or shipping can change. Review your path weekly, adjust dates and responsibilities, and notify stakeholders so everyone works from the latest plan.What’s the risk of not having a critical path?

Missed launches, rush fees, excess freight costs, stressed teams and poor supplier accountability. Without a clear path, delays stay hidden until it’s too late to fix them. PLM links your tasks to live product data. You can assign owners, set dependencies, track slippage and get alerts when dates are at risk. It removes spreadsheet chaos and keeps suppliers and internal teams aligned.Is the critical path only for big brands?

No. Any brand working with suppliers benefits. Even small teams gain clearer timelines, fewer surprises and better cash-flow planning when they use a simple, living critical path.”What’s the difference between a critical path and a Gantt chart?

A Gantt chart is a visual timeline. The critical path is the actual sequence of must-hit tasks that set your earliest finish date. You can show a critical path on a Gantt chart, but they are not the same thing.Take control of your critical path

Fashion is fast. Without a critical path, it’s easy to get lost in the chaos of suppliers, samples and shifting deadlines. With one, you bring clarity and control back to your process.

At Bombiix, we’ve built critical path management straight into our PLM so you can focus on creating products while staying confident about your timelines.