What is a Purchase Order and How Do You Create One?

A purchase order (also known as a PO) is a list of products or services a company agrees to buy from a supplier. It includes the type and quantity of products to be bought, as well as the agreed price.

Once the supplier agrees to a purchase order, it becomes a legally enforceable agreement. That means the supplier has to supply the goods or services listed in the PO, and the buyer has to pay for them as agreed.

Every purchase order has a unique number (sometimes called a purchase order number or PO number) so it can easily be tracked, audited and referenced back to.

Purchase orders are used across all industries. They’re an essential tool for managing supply chains. So it pays to understand how they work, and how you can use them.

How does a purchase order work?

The purchase order process begins when the buyer identifies the need for a product or service. It could be something like an order of fabric for a run of shirts, or it could be the services of a construction company. Purchase orders are usually used for higher-value procurement, but there’s no specific limit.

Then, the purchase request needs to be agreed on internally. Usually, there’s a sign-off process in the organisation for this. It can vary depending on the value of the purchase – for example, lower-value orders might just need manager sign-off, while higher-value ones may need to be approved by finance.

Next, the buyer compares suppliers to make sure they get the best value for money. At larger organisations, this is often done by a dedicated procurement team.

Once the request has been reviewed and agreed, a purchase order is created. This specifies important details like the products to be supplied, the agreed price and the delivery date. Usually it’s reviewed again at this stage. Purchase orders often deal with significant sums of money, so it’s important to get them right.

Then, the purchase order is sent to the supplier. Depending on the relationship between buyer and supplier, things like final price and delivery date are often negotiated at this point.

The supplier reviews the purchase order to make sure they’re happy they can fulfil it, then get to work putting the order together. They’ll usually confirm delivery dates and update the buyer on progress as they go.

When everything is ready, the supplier dispatches the goods to the buyer. When they receive the order, the buyer checks over everything carefully to make sure all the terms of the purchase order have been met. If there are any problems, they report back to the supplier and negotiate a solution.

Once everything is confirmed and everyone is happy, the buyer’s finance department verifies the details of the purchase order before paying the supplier. Often, finance departments will wait until they have several POs then pay them together. It’s worth checking up on this and making sure it won’t hold up the payment as agreed.

Once the goods are received and payment has been made, the purchase order and any other relevant documents are filed away for future reference and auditing.

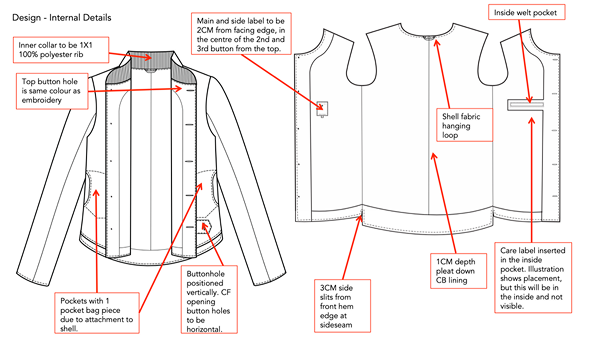

What does a purchase order include?

A purchase order is a detailed, legally binding document, and it includes a lot of information. Certain information has to be included. There are several other details that buyers often choose to include.

Essential information

A purchase order has to include the following information.

PO number

Every purchase order needs a unique number to identify it for tracking and reference purposes.

Issue date

This is the date that the buyer creates the purchase order and sends it to the supplier.

Buyer details

These include company name, address and contact details.

Supplier details

The supplier’s company name, address and contact details.

Item description

Detailed information about the products or services being purchased, including things like model number/SKU number, specifications, sizes and any other relevant information.

Quantity

The number of each item or service being purchased.

Unit price and total cost

The agreed price per unit and the full order value. This usually includes any taxes and supplier discounts.

Delivery information

Expected delivery date and shipping instructions.

Payment terms

The agreed terms for payment such as 30 or 60 days from the date of the invoice, or an instalment plan.

Terms and conditions

Things like warranty information, cancellation policies and any other contractual requirements.

Approval signatures

Authorisation from both the buyer and the supplier.

Common additional fields

Buyers can add any additional information they need to the purchase order. This varies between organisations, but often includes the following.

Budget codes and internal references

These are used for accounting purposes and expense tracking.

Subtotals, taxes and grand total

Buyers often include itemised cost breakdowns.

Special instructions

Any other information that’s needed for safe delivery of the product – things like handling requirements, regulatory notes or any other unique requests.

What’s the difference between a purchase order and an invoice?

Purchase orders and invoices are often part of the same buying process, but they’re different documents with specific purposes.

A purchase order is issued from the buyer to the seller. It signals their intent to purchase goods or services. It’s sent before the supplier starts preparing the goods, and it’s a contractual agreement that sets out the terms for a purchase.

An invoice is issued from the seller to the buyer. It’s a request for payment for goods or services that have already been delivered or fulfilled and is sent after delivery.

Why are purchase orders so important in business?

Purchase orders are vital in business because they give both buyers and suppliers control and clarity in the purchasing process. Suppliers know exactly what they need to supply well in advance. Buyers know what they’re going to receive, and when.

They’re even more important for organisations with complex supply chains, where production relies on the delivery of parts from many suppliers, often on a just-in-time basis.

Purchase orders give buyers a detailed overview of their supply chain. This lets them make sure production lines can run smoothly without needing storage space for many components. They make it easier to control finances and budgets too, as there’s a record of exactly what is being spent and when.

They also provide legal protection over supply chains. Once accepted, a purchase order is a detailed, legally binding contract between the buyer and seller. If that contract is not met, both parties are protected.

Should I use purchase orders for my business?

That depends. Some buyers and sellers – especially larger organisations – require purchase orders to do business. So, as your company grows, and you work with larger quantities and bigger suppliers, purchase orders will become essential.

It’s worth thinking about how you’ll integrate purchase orders – and the associated audit trail – as you scale your business. It’s a good idea to put the process in place before it becomes necessary, rather than trying to implement it retrospectively.

Using an integrated system like Bombiix can make the process much simpler and save you significant time and stress.

How does Bombiix help with purchase orders?

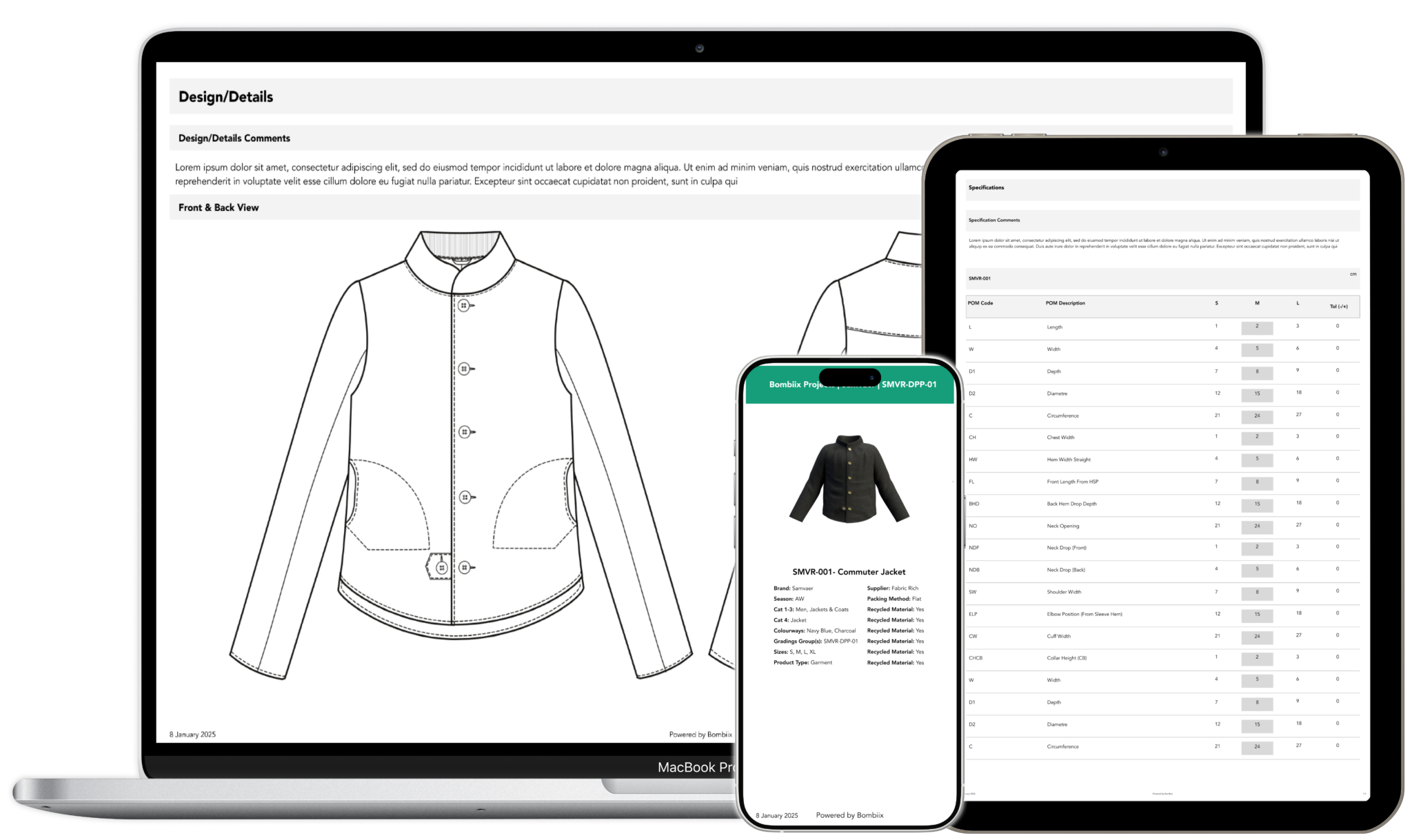

Bombiix is an integrated product lifecycle management (PLM) system. It manages your products from inception to disposal. It can also manage your digital product passports (DPPs).

As part of Bombiix’s product management, it can also generate and manage your purchase orders automatically. Because they’re directly linked to your cost negotiations and product management system, your purchase orders will always be accurate. They’ll also be filed away safely, easily retrievable for auditing purposes.

Learn more about how Bombiix can help your business grow

Bombiix is designed to scale with your business. It’s easy to use and comprehensive, so product management is as simple as can be. And, with tiered pricing options that start with a completely free option, you can easily see if it suits your business needs.

You can find out more about how much Bombiix costs on our PLM pricing page. Or if you want to see how Bombiix could work for you, you can get in touch to book a demo call.