How Do PLM Systems Integrate With Other Software?

Product lifecycle management (PLM) software makes running your business simpler and more efficient. One of the ways it does this is through integration.

A good centralised PLM system, like Bombiix, integrates seamlessly with all your systems and software. It also integrates with external suppliers and other partners, so you have a single source of truth for every single element of your product’s lifecycle.

Done right, a well-integrated PLM can transform your business. Let’s find out how.

PLM integration with MES and ERP

A MES is a Manufacturing Execution System and an ERP is an Enterprise Resource Planning system. Product life cycle management in ERP and with a MES, provides a comprehensive, cohesive digital environment for managing your products and your business.

PLM with MES

A PLM provides your MES with up-to-date product designs, bill of materials (BoM) and engineering change orders automatically. The MES then uses that data to run and monitor manufacturing processes in real time. That means your production line is always using the most current designs and materials.

In a fully integrated system, the MES then feeds production and quality data back to the PLM so you have the data you need to improve the manufacturing process, and everything is transparent and traceable.

PLM with ERP

A PLM gives your ERP systems the detailed product data they need for you to plan and organise your business operations.

With a PLM and ERP putting all that information in the right place, in real time, you can plan your resources, procurement and scheduling to a granular, precise level.

And of course, the ERP system will feed right back into your PLM and your MES so you can adjust production on the fly.

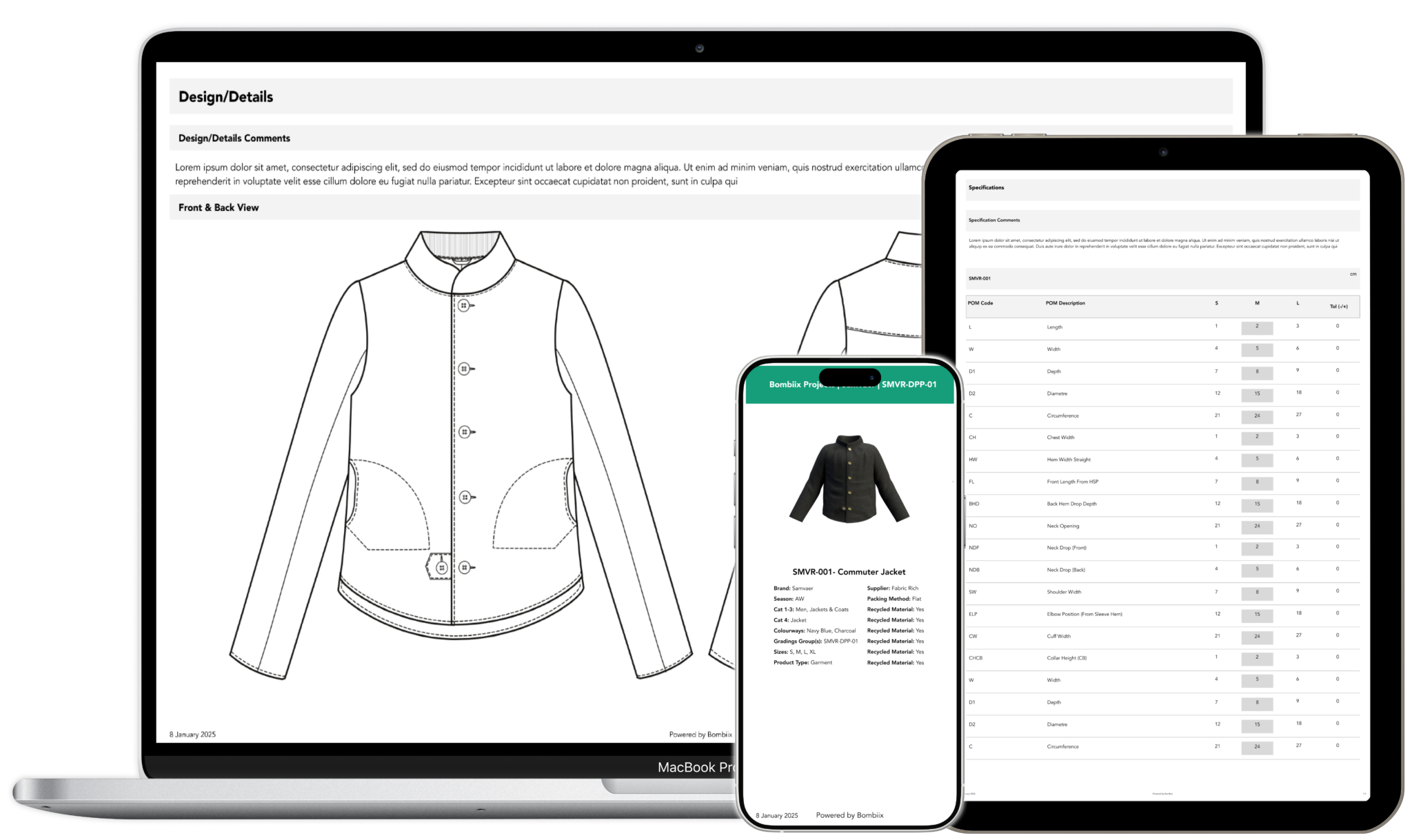

PLM and DPP

DPPs (digital product passports) are being rolled out all over the world. If you sell physical products – and especially if you sell them in EU – you’re probably going to have to adopt DPPs sooner than later. And a PLM system will integrate seamlessly with your DPP system to make the whole process much simpler and more efficient. Some, like Bombiix, even come with a DPP solution already built in.

Centralised data

Your PLM is the single source of truth for things like product designs, manufacturing processes and manufacturing data. Anything anyone needs to know about a product is in there and easily searchable. This data can be automatically compiled and structured to populate a product’s DPP.

Automated workflows

PLMs can be set with automated workflows to continually update DPPs with new data as it happens. This means your DPPs are always up to date, and also reduces the need for manual input significantly.

Stay compliant

Having a well set up PLM makes it much easier to collate and manage the product data you need to comply with regulatory DPP frameworks.

Integration with all your apps

One of the biggest benefits of a cloud-based PLM system is that it helps your teams work together more collaboratively. One of the ways it does this is by integrating closely with the many different apps your business uses on a daily basis.

This means that teams from all over your organisation – and potentially all over the world – can easily access files and information from other teams, all through a single simple interface.

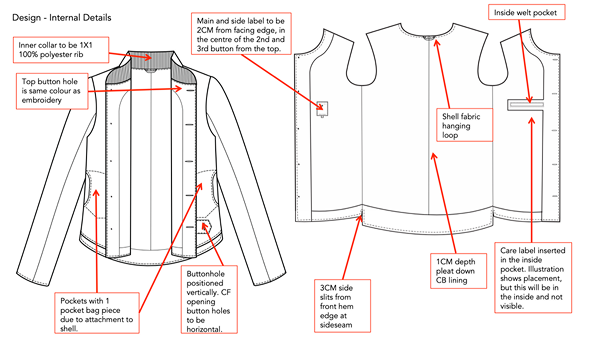

PLM and CAD

PLM systems integrate seamlessly with popular CAD (computer aided design) packages so all design data is managed, controlled and easily accessible. CAD PLM files and drawings are stored in a single, central repository and cross-referenced with related data like BoMs, specifications and revision data. This creates a single source of truth, where the most current information data is easily available to anyone who needs it.

Transparent integration

Most PLMs use APIs, preconfigured connectors or middleware to automate the transfer of data to the PLM system. This means the process is invisible to the designer, with no extra tasks for them to complete.

Automatic notification

Because the two systems are completely integrated, you can set changes in CAD files to trigger notifications in the PLM, so everyone is up to date with current revisions. This helps to minimise expensive errors and rework.

Multi-format support

It doesn’t matter if your teams use different CAD packages for different products, or at different points in the design process. A PLM supports multiple different CAD systems so you can manage different workflows in a single environment with no compatibility issues.

PLM and Excel

If you’re new to PLM software, with all your product management stored in Excel spreadsheets and Word documents, you may be concerned about the effort of moving over to a dedicated PLM solution.

You needn’t worry, because PLM systems integrate seamlessly with existing Excel spreadsheets, both for transferring data to the new system and for ongoing data sharing.

Data flows both ways

Many PLMs let data flow both to and from Excel, completely automatically. So, someone can work on a BoM or other file directly in a spreadsheet, and the changes will automatically upload to the PLM.

Data import and export

Users can export product data from a PLM to work on in a familiar spreadsheet environment like Excel, then import it back in so the data remains consistent.

Bulk import

If your data is stored on spreadsheets but you’re ready to move to a PLM, most systems will give you the option to import all of your data in one go. Then you’re all set to start work in your new, efficient PLM environment.

Reduced errors and improved control

As all the spreadsheet data is stored centrally on the PLM, it’s much easier to keep track of where and how changes are made. This helps ensure that all teams are working from the most up to date versions of files.

Powerful when used correctly

It’s important to note that, while hosting spreadsheet data in a PLM is a useful tool, it shouldn’t be used as a replacement for the PLMs core functions. Excel is not designed for complex lifecycle management.

PLM and ecommerce

If you sell your products direct, through your own ecommerce platform, your PLM will integrate with that too. That means accurate, up to date product information on your website, faster time to market and much greater control over complex product catalogues.

Link to PIM

Your PLM can provide structured product data (like tech specs, images, materials and compliance info) to your PIM (product information management) system. The PIM can then adapt this information for different platforms like your own ecommerce site as well as marketplaces like Amazon.

API or middleware connection

Modern PLMs connect to ecommerce systems through APIs or dedicated middleware solutions. This means that data connections in one system are quickly reflected in the others. For example, if a design or material change is made, product pages can update automatically.

Syndication and validation

A PLM automatically validates product data for different channels and platforms. So, things like image sizes, required fields and regulatory codes are created and updated automatically. This saves repetitive work, reduces listing rejections and keeps your brand consistent.

Consistent data

Having a single source of truth for your data means everything, on every platform is up to date and accurate.

PLM and creative apps

Keeping on top of the creative assets for your products is a challenge all of its own. Modern PLMs integrate directly with creative solutions like Adobe’s Creative Cloud suite, and apps like Illustrator, Photoshop and InDesign to streamline creative workflows and improve collaboration between teams.

Direct plugin access

Many PLMs now provide direct plugins for popular creative apps like Illustrator, Photoshop and InDesign. That means your creative and design teams can create and edit artwork in their favourite apps and publish them directly to your PLM.

Easier feedback and review cycles

People throughout your business – and beyond, if needed – can easily access, view and comment on creative assets in your PLM. That means feedback is taken care of through a single, transparent system – no need to search through emails to find the comment you need to action.

Faster product development

Design teams can access standardised colour libraries, fabrics, templates and product data from the PLM directly through their creative apps. This makes the creative process much more efficient, and reduces your time to market.

Choosing the right PLM for your integration needs

If you’re installing a PLM system, it makes sense to think about how it will integrate with your existing software and solutions. The more closely integrated your disparate solutions are, the more they’ll help to bring your teams and processes together into a single, coherent whole.

That’s why Bombiix is designed from the ground up to integrate seamlessly with all the most popular apps and systems, from the Adobe Creative Cloud Suite and Excel to ecommerce platforms like Shopify and enterprise-level MES and ERP solutions.

Chances are, if you use it, Bombiix will talk to it.

Bombiix also comes with a comprehensive DPP system built in. So if you need to get your business DPP compliant too, Bombiix is the perfect solution.

You can find out more about Bombiix PLM here.